Grease Trap

FOG (fats, oils, and grease) in drains is a serious problem that impacts public sewer lines. Clearing these blockages requires specialized equipment and time.

Restaurants and other food service establishments must install grease traps or interceptors to prevent fatty waste from entering the sewer system. These traps must be cleaned on a regular basis. Contact Grease Trap Perth now!

A grease trap is a receptacle that kitchen wastewater flows through before it enters the sewer waste system. The trap reduces the amount of fats, oils and grease (FOG) that gets into the pipes and creates blockages. It also helps foodservice businesses comply with FOG regulations.

The reason restaurants need to have a grease trap is because the plumbing system isn’t designed to handle FOG. When food grease cools down, it becomes a waxy substance that can adhere to different surfaces and create massive blockages in the plumbing. Those blockages lead to costly repairs for the property owner, as well as public health and safety risks.

When a building’s drains aren’t properly managed, the FOG can reach the sewer system and cause sanitary sewer overflows. These overflows are a serious public health issue that requires special equipment, time and manpower to clear up.

Luckily, a properly-functioning grease trap can help prevent these overflows and backups. Here’s how it works:

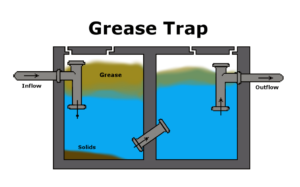

When wastewater goes down a drain, it slows down significantly as it passes through the trap. As it does, the water separates into three layers: solids on the bottom, wastewater in the middle and FOG on the top. FOG rises to the surface because it’s less dense than the surrounding water. The trap captures the FOG, keeping it away from the sewer system and reducing the risk of sewage backups in kitchens and other parts of the building.

There are several types of grease traps available, and the one your restaurant needs will depend on the flow rate and the plumbing layout. A reputable commercial plumber will be able to assist you with this process and recommend the best option for your business.

Once the grease trap is installed, it’s important to educate employees on how to properly use the kitchen plumbing. That means using drain covers in sinks, scraping food into trash cans instead of down the drain and rinsing dishes before putting them in the dishwasher. You should also have the grease trap pumped on a regular basis to keep it clean and functional. A reputable service provider can create a schedule for you that’s compliant with local and state regulations.

As the name implies, grease traps (and interceptors) are boxes within the drain run between kitchen sinks and the sewer system. They are designed to filter out the fats, oils and greases (FOG) from kitchen wastewater before it enters the sewer lines, where it can block other drainage fixtures like toilets and cause sanitary sewer overflows.

Invented in the 1880s, the technology behind these units has remained essentially unchanged since then. FOG accumulates in kitchen wastewater and eventually solidifies, floats to the surface and is separated from clean water as it passes into a second chamber within the trap. The captured grease is then emptied into a storage tank or removed by licensed professional cleaners for proper disposal.

Because a blocked grease trap can lead to costly property damage and downtime for your business, it’s important to have one installed correctly. Grease traps should be located as close to the source of FOG as possible, usually underneath a sink in your kitchen, and placed on a level surface to prevent pooling. They should also be properly sized so that the wastewater from your sinks is able to flow through the trap without overloading it.

In addition, you should install a cleanout tee on the inlet and outlet pipes to make it easier to access your grease trap for cleaning and maintenance. FOG in kitchen wastewater can create toxic sulfuric acid that destroys pipelines downstream, so the tee helps protect the entire plumbing system.

Most municipalities require grease traps or interceptors be installed at locations that prepare food items to help reduce the amount of FOG that ends up in sewage systems and contributes to sewer overflows. If you don’t have a grease trap or interceptor installed, you may be subject to fines and other penalties by your local government.

Grease traps can be expensive to purchase and install, but the investment is well worth it. Aside from being a vital safety measure for your business, it’s a good way to protect the environment and keep your customers safe from foul odors and dangerous FOG buildup in sewer lines. Regular cleaning and maintenance by a certified grease removal specialist can also ensure your trap is in compliance with FOG regulations and is working effectively.

Grease traps need to be pumped regularly of both solid waste and liquid grease. This is typically done by licensed professional technicians who can also take care of record-keeping and disposal requirements and keep you in compliance with city regulations.

The frequency of your pumping schedule depends on the size and volume of your traps as well as kitchen operation and productivity. Ideally, you want to drain out your traps at least once a month or whenever they reach a quarter of capacity. Overfull traps will begin to smell and can lead to clogs in sink drain lines or even sanitary sewer overflows.

During the pumping process, your technician will remove the lids, sides and baffles of the trap to make sure all FOG is removed. They may also use a shop vacuum to suck out the most solidified grease waste to fully empty the tank. They will then clean the tank and all components with warm water and soap, scrubbing hard-to-reach areas. Then, they will flush the trap with clean water to rinse off any remaining soap and grease residue.

Once the tank is empty, they will mark it with a dowel and write down the results on a FOG (fats, oils and grease) pump out report, which your city requires you to have on file. They will also give you a copy for your records.

Aside from having your grease traps pumped and cleaned, there are other things you can do to prevent overflows and costly cleanups. For example, encourage your cooks to minimize the amount of solid food waste that goes down the drain and to use a strainer in their sinks to catch any large pieces. Also, avoid using chemical drain openers and degreasers as these products can actually cause the grease to break down and flow straight down into the sewage system, leading to clogs in your pipes and sewer lines.

It is also a good idea to install a visible indicator on your grease trap to let you know when it is nearing capacity. This will help you avoid a grease trap overflow, which can lead to expensive cleanups and fines from your city.

Many restaurants, commercial kitchens and other businesses with grease traps find it helpful to work with a professional service provider that can handle the entire process of maintenance and repair. A knowledgeable service technician can help prevent costly backups and overflows, and will also inspect the trap for signs of visible damage that needs attention by a plumber.

Taking care of the grease trap is essential to preventing costly issues with city sewage lines and drains in the establishment’s kitchen. In fact, most cities require that grease traps be used to ensure that fats, oils and grease (FOG) don’t clog and block municipal sewer lines, leading to costly overflows and repairs for the establishment.

The best way to avoid these expensive issues is to have the trap pumped and cleaned regularly. A regular schedule of pumping and hydrojetting can keep the trap in good working condition, extending its lifespan and helping to prevent the need for repairs.

One of the most common problems with grease traps is a clog that affects one or both of the two compartments of the trap. This can happen in the incoming line, the outgoing line or the crossover line that connects the two. Clogs can be caused by a variety of things, including excessive food waste or even solidified grease from cooking.

Foul odors that come from the trap are another sign of a problem. If the smell is strong and persistent, a full cleaning with hydrojetting may be necessary.

Inspect the couplings at the point where the waste water enters and leaves the trap. If they are not water-tight, this is a sign that they need to be replaced.

A grease trap that is badly corroded or has internal parts that are damaged will need to be replaced. Fortunately, this is a simple process and can be done by any experienced plumber. The grease trap will need to be cleaned first, then a metal plug can be inserted into the hole. You can use a stainless steel machine screw with a washer behind it or a piece of rubber gasket cut to size.